▎Description

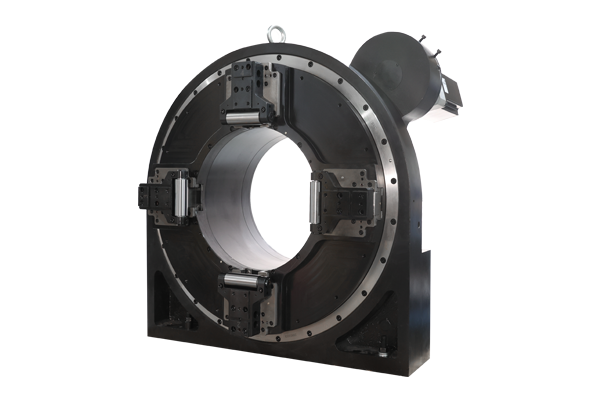

DRK-520 Laser Chuck

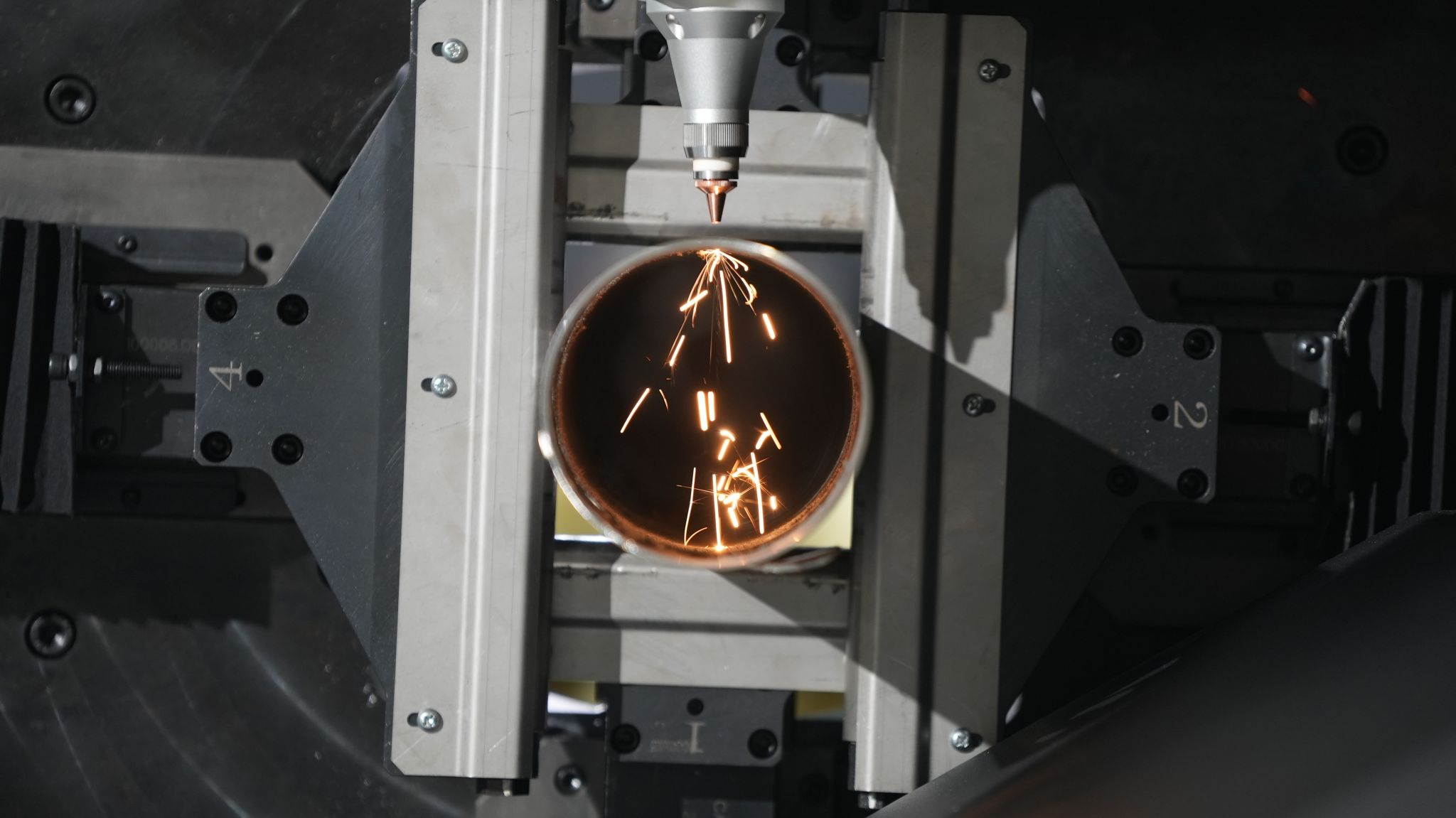

Metal tubing is a widely used material for fitness equipment manufacturing, chemical piping, heavy industrial manufacturing and other industries. The shape, diameter, weight, and thickness of metal tube can vary from industry to industry and application to application, which places higher demands on metal tube cutting technology. Traditional methods of cutting heavy tube is mainly flame cutting and plasma cutting, but these methods are easily limited by the operator’s cutting level, resulting in poor quality of the cut finished product with many defects, and repeated cutting increases time and tube material costs.

- Therefore, in response to this situation, laser cutting technology has gradually become the mainstream of heavy tube cutting. Compared with traditional cutting methods, laser cutting technology can achieve high precision and high efficiency cutting, and it can also achieve self-centering production, which greatly improves production efficiency and quality.

- Dairuike launched the DRK-520 Heavy Series Laser Chuck in 2020 to meet the expanding demand of the heavy tube industry for processing heavy channels, angles and other profiles. The chuck is capable of processing profiles up to 508mm in diameter and 1500kg in weight, which can meet the processing needs of large tube and has high market competitiveness and application prospects.

- The laser chuck has the feature of large through diameter, which can process various metal tube with the diameter range of 90-508mm, and can clamp up to 45 I-beam and channel steel to meet the needs of customers. Moreover, this pneumatic chuck also supports complex cutting processes such as beveling, cutting off, round hole, waist round hole, etc., which ensures customers’ mass production, greatly improves production efficiency and ensures product delivery time.

- The laser chuck has the characteristics of high repeatable positioning accuracy, stable and reliable clamping, etc. The chuck bearing is supported against the front, with a short cantilever structure, the chuck is highly rigid, and the chuck vibrates little when the bent tube is cut off, ensuring cutting accuracy and quality. In addition, the 520 laser chuck clamping and accuracy are two in one, which can provide efficient and stable double guarantee for large tube processing.

- By using four chucks to clamp the tube at the same time during cutting, it maximizes the use of the tube and avoids waste, allowing for true zero tail material, saving the customer tube loss, improving productivity and reducing production costs.

Dairuike 520 laser chuck follows the industry trend of multi-species heavy tube processing and is rapidly applied in bridge and tunnel, construction machinery, steel bridge and other industries, providing the power and support for the transformation and upgrading of enterprises.

▎Three/four chuck design

Dairuike 520 three/four chuck laser cutting machine provides a more efficient solution for heavy metal tube processing. Here are its main features:

- The 520 laser chuck is optional for side mounting: it adopts a three/four chuck design, which can easily clamp tubes with an extra length of 12 meters and an overweight of 1500kg. Through pneumatic clamping, the clamping force is large and adjustable, ensuring stable clamping of heavy tubes during cutting, avoiding loosening and slipping and deformation of light and thin tubes, thereby ensuring cutting accuracy.

2. 0 tailings: 520 laser chuck three/four chucks laser cutting machine adopts reversing cutting and a variety of clamping cutting modes to achieve 0mm infinite tailing cutting. This means that the utilization rate of materials has increased by 100%, saving production costs.

3. Break through the load-bearing limit of heavy tubes: Our laser cutting machine can effectively cut round tubes with diameters of φ90mm-φ508mm and square tubes with diameters of □20mm-□365mm. At the same time, it supports the clamping of 12-meter ultra-long heavy tubes, and the maximum load can reach 1500kg, breaking through the limit of heavy-duty tubes.

These features make our three/four chuck laser cutting machines ideal for processing heavy metal tubing. It can improve production efficiency, save material cost, and guarantee cutting quality. Whether it is in heavy industry machinery, steel structure building, building construction, machinery manufacturing, bridge engineering, greenhouse or communication tower, it can provide reliable and efficient solutions for the processing of heavy metal tubes.

▎Frequently Asked Questions

Q: What parameters should be provided to get a proper quotation?

A: Use the model (plate tube machine or tube cutting machine), the specification and size of the clamped tube (such as: round tube diameter, wall thickness, length, etc.).

Q: Can I visit your company to understand the products before delivery?

A: You are welcome to come to Dai Ruike for guidance.

Q: What is your delivery time?

A: within 15-35 days after the contract is signed

Q: What is the packaging condition of the laser chuck?

A: Generally, we pack our goods in standard export wooden boxes.

Q: What are the advantages of Dairuike Laser Chuck?

A: ①Independent research and development capabilities, with a professional R&D team, has provided complete chuck solutions for 200+ customers

②Independent processing capability, the introduction of precision machining equipment (Korea Doosan machining center, American Haas machining center, Japanese Mazak CNC lathe)

③Professional QC team guarantees the high quality of products

④Provide a complete service system (build a full-service system from the three links of pre-sale, sale and after-sale)

Q: What is your payment method?

wire transfer

▎Performance parameter

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm2) |

Repeatability (mm) |

Rotary precision mm |

| Φ1140 | Φ520 | 580±0.05 | 1250 | 1050000 | ≤0.10 | ≤0.10 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (M pa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 80 | 1160 | 90-508 | 0.3-0.8 | 50 | ≥5 | 12 |

▎Application