▎Description

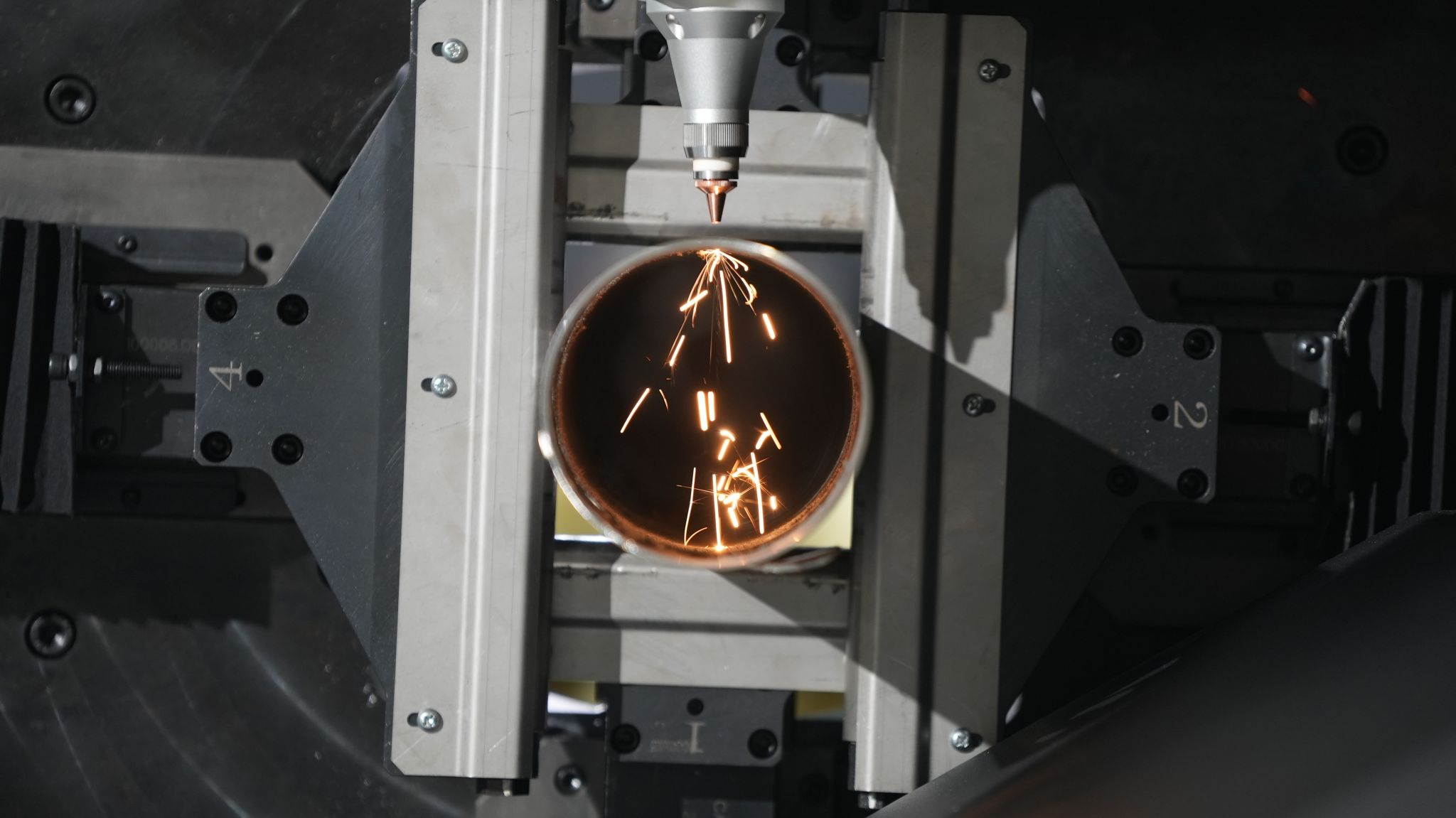

The production and consumption of metal pipes are increasing day by day, and the demand for pipe processing is increasing. The birth of laser pipe cutting machines has injected new blood into pipe processing. As an important component of the laser pipe cutting machine, the cnc fiber laser tube chuck plays a vital role.

- The DRK-280JL cnc fiber laser tube chuck is upgraded with a square hole through-hole design, which can be used for all types of materials and special-shaped tubes. The cnc fiber laser tube chuck is independently developed by DaiRuike. It adopts channel steel jaws, wider clamping surface, and higher cutting accuracy. can fully meet the cutting needs in different scenarios. Compared with the common chucks with exposed transmission gears in the market, poor dust protection, low safety factor and other pain points, the Dairuike cnc fiber laser tube chuck has helical gear transmission, built-in gears, good dust resistance, no teeth jamming, reduced maintenance frequency, and convenient use.

- DRK-280JL is a square-hole cnc fiber laser tube chuck designed and developed for the pain point that round-hole chucks cannot clamp square pipes to the maximum. It can process up to 280mm square tubes, refreshing the maximum processing diameter of similar chucks for square pipes. The above can be processed in large batches and flexibly deal with various types of materials and special-shaped pipes.

- DaiRuike DRK-280JL cnc fiber laser tube chuck improves the conventional round hole chuck, the size range of the processed pipe is larger, the bearing capacity is increased, and it conquers the metal pipe market that has been tested many times.

- DRK-280JL cnc fiber laser tube chuck adopts wide and narrow clamping, stable clamping is suitable for various profiles, the processing range of pipe diameter is 10-280mm, one-piece casting, the reducer is installed stably, and can be selected from multiple angles. Seat guide adjustment, easy to adjust. The clamping transmission mechanism has good sealing performance, high efficiency and dustproof, high transmission efficiency and synchronization precision. It greatly satisfies the laser cutting of various types of pipes, ensuring the stability of processing and the cutting accuracy of pipe fittings.

- This cnc fiber laser tube chuck is a supporting equipment for the laser cutting machine that can clamp and feed the tube when cutting the pipe. It can clamp various specifications of round pipes, rectangular pipes, channel steels, I-beams, angle steels, special-shaped pipes, etc., taking into account all materials.

▎Questions About Chucks

Q: What is a cnc fiber laser tube chuck?

A: The cnc fiber laser tube chuck is one of the important accessories of the laser cutting machine, which is used to clamp and fix the pipe to be cut. It ensures the accuracy and stability of the pipe during cutting through precise clamping and stable support.

Q: What are the advantages of cnc fiber laser tube chucks?

A: cnc fiber laser tube chuck offers several advantages. First of all, it can clamp various specifications of round pipes, square pipes, channel steel, I-beam, angle steel, special-shaped pipes, etc., and is suitable for processing various materials. Second, the cnc fiber laser tube chuck has high clamping force and repeatable positioning accuracy, which can ensure firm clamping and precise cutting of pipes. In addition, the cnc fiber laser tube chuck is easy to maintain, durable and reliable, and can maintain good performance in long-term use.

Q: What are the precautions for the installation and use of the cnc fiber laser tube chuck?

A:The installation and use of the cnc fiber laser tube chuck requires attention to the following: First, ensure that the cnc fiber laser tube chuck is installed and adjusted correctly to ensure uniform clamping force and stable clamping of the pipe. Secondly, when using, operate according to the requirements of the operation manual, abide by safety regulations, and pay attention to personal protection measures. Also, perform regular maintenance and maintenance on the cnc fiber laser tube chuck, keep it clean, and replace worn parts as needed.

▎Performance parameters

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (kg) |

Inertia (Kg.cm)2 |

Repeatability (mm) |

Rotary precision (mm) |

| Φ645 | 290×290 | 330±0.05 | 275 | 98290 | ≤0.05 | ≤0.05 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (Mpa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 73 | 330 | 10-280 | 0.3-0.8 | 150 | ≥1 | 12 |

▎Application

The application solution of cnc fiber laser tube chuck in the door and window guardrail industry has the following advantages:

Applicable to a variety of pipes: the cnc fiber laser tube chuck is suitable for square pipes, rectangular pipes, round pipes, oval pipes and special-shaped pipes commonly used in the door and window industry, as well as tubular profiles such as angle steel, channel steel, I-beam, and T-shaped steel. It can meet the cutting needs of different pipe materials, and provides greater flexibility for the production of door and window guardrails.

Diversified processing capabilities: In addition to automatically centering and clamping pipes, the cnc fiber laser tube chuck can also perform processing operations such as oblique cutting, hole opening, engraving, and rotating hole opening. This makes the design of door and window guardrails more diverse, and can achieve more refined and personalized processing requirements.

High precision and high efficiency: Compared with the traditional stamping process, the cnc fiber laser tube chuck does not exert pressure on the workpiece during processing, so it can avoid the problem of deformation of the workpiece. It can realize one-time molding, reduce the need for secondary processing, and improve production efficiency. At the same time, laser cutting has high-precision cutting capabilities, which can meet fine processing requirements and ensure the quality and aesthetics of door and window guardrails.

Multi-material adaptability: The cnc fiber laser tube chuck is not only suitable for metal pipes, but also suitable for pipes of different materials, such as carbon steel pipes, stainless steel pipes, aluminum alloy pipes, copper alloy pipes, titanium alloy pipes, etc. This provides a greater space for material selection for the door and window guardrail industry, which can meet the needs of different customers.

To sum up, the cnc fiber laser tube chuck has the advantages of being suitable for a variety of pipe materials, diversified processing capabilities, high precision and high efficiency, and multi-material adaptability in the door and window guardrail industry. It provides greater design flexibility and processing efficiency for the production of door and window guardrails, so that the door and window guardrails can meet the market’s requirements for beautiful, generous and stylish decoration styles.