▎Description

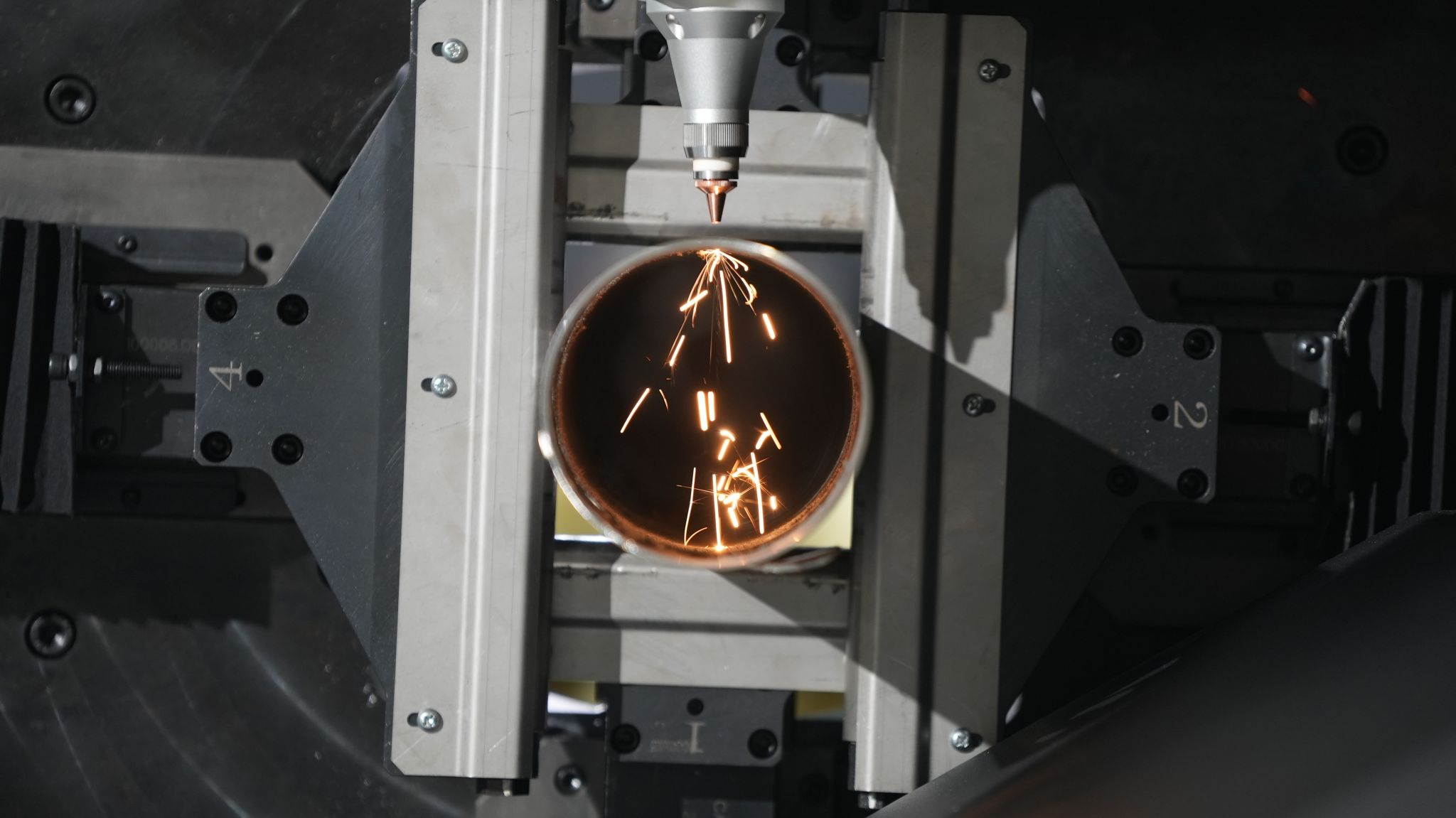

DRK-240JL Pipe Chuck adopts a square through hole structure design, which can clamp pipes of various shapes to meet the different processing needs of users. Compared with the traditional round hole pipe chuck, its design breaks through the limitation of the round hole, and it can clamp the square tube to the maximum extent, and the square and round can take all, which greatly improves the utilization rate of the tube.

- The design of the 240JL pipe chuck is very simple and flexible. It is installed with an integrated casting and a stable reducer, which can be more worry-free during installation and debugging. At the same time, the chuck can be selected from multiple angles, and the adjustment of the stop guide is also very convenient, so that the user can complete the adjustment more quickly. Not only that, the 240JL pipe chuck has a very large clamping force and a stronger load-bearing capacity, which can easily clamp pipes of various shapes, thereby ensuring the stability and precision of the workpiece during processing.

- The standard channel steel jaws of the 240JL laser chuck can clamp large profiles, making the clamping process more stable. The two clamps can hold pipes up to 260kg, which can meet various processing needs of users. At the same time, the pipe chuck adopts a helical gear transmission mechanism, and its transmission efficiency and synchronization accuracy are very high, which can realize precise positioning and clamping of the workpiece, thereby improving the processing accuracy and efficiency.

- In terms of use, the operation of the 240JL laser chuck is also very simple and flexible. The user can quickly complete the clamping adjustment only through the spigot guide adjustment, thereby improving work efficiency. In addition, the fully sealed transmission mechanism of the pipe chuck can effectively prevent dust and has excellent protection performance, which can prevent cutting dust from entering the inside of the gear, thereby reducing maintenance frequency and extending the service life of the chuck.

▎Advantages of pipe chuck

1.High transmission efficiency and synchronization precision: The pipe chuck adopts an efficient transmission mechanism, which can realize high transmission efficiency and precise synchronization operation. This helps to improve processing efficiency and processing quality.

2.Large size range: Compared with traditional round hole pipe chuck, pipe chuck can be applied to a wider range of pipe sizes. They are capable of clamping thin tubes or fragile tubes without causing flattening, breaking through the limitations of traditional round hole pipe chuck and meeting the market’s demand for a wider clamping range.

3.The installation position of the reducer is adjustable: the installation position of the reducer of the pipe chuck can be adjusted to adapt to different processing requirements and machine tool structures. This increases flexibility and adaptability.

4.Good dust-proof effect: the design of the pipe chuck can provide better dust-proof effect, reduce dust and pollutants from entering the inside of the chuck, thereby improving the pollution resistance of the chuck. This helps protect the life and stability of the chuck.

To sum up, the pipe chuck has the advantages of high transmission efficiency, high synchronization accuracy, strong size adaptability, flexible installation position, and improved processing efficiency and quality. This makes the pipe chuck an important equipment in the field of pipe processing, providing users with high-quality processing solutions.

▎Performance parameters

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (kg) |

Inertia (Kg.cm)2 |

Repeatability (mm) |

Rotary precision (mm) |

| Φ645 | 240×240 | 325±0.05 | 268 | 91900 | ≤0.05 | ≤0.05 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (Mpa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 110 | 220 | 10-230 | 0.3-0.8 | 150 | ≥1 | 12 |

▎Application