▎Description

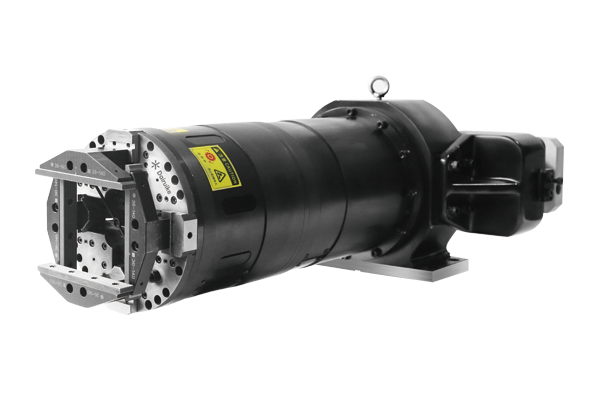

The laser pneumatic chuck is an essential part of the laser pipe cutting machine, which can firmly clamp the pipe to ensure the stability and precision of the cutting. Among them, DRK-220JZ laser rear chuck is equipped with 240JS laser front chuck, which is suitable for processing pipe fittings with pipe diameters within the range of 10-220mm.

- The laser pneumatic chuck rear chuck adopts a new barrel design, with a larger clamping stroke and fewer types of jaws, which makes the operation more convenient, minimizes the waste of pipes, and improves the utilization of pipes. At the same time, the integrated design of the 220JZ pneumatic chuck rear chuck reducer installation allows more flexible installation of the reducer.

- The 220JZ pneumatic chuck rear chuck also has the characteristics of high precision and high synchronization precision, which can realize precise positioning and clamping of workpieces, and improve processing precision and efficiency. The integral support seat structure of the rear chuck enhances the stability of the supporting load and ensures the accuracy and stability of the machining process. In addition, the rear jaws of the 220JZ Pneumatic Chuck are made of steel, and the surface has been specially treated, which has excellent properties such as high temperature resistance, wear resistance, and corrosion resistance. Tightness keeps the workpiece balanced and stable.

- 220JZ laser pneumatic chuck rear chuck is widely used in metal processing, industrial manufacturing and other fields, and is one of the important equipment to improve production efficiency and product quality. It can provide a stable rear chuck support for laser cutting, ensure the stability and precision of the workpiece during processing, and bring higher benefits and better products to the enterprise.

▎Attention to the use of Pneumatic Chuck

1.Ensure correct use: When using a Pneumatic Chuck, it is very important to ensure the stable operation of the chuck. Correctly operate and maintain the equipment to avoid problems caused by incorrect use methods, such as abnormal air pressure, weakened clamping force, poor clamping accuracy, etc. Understand the operation manual and related instructions of the chuck, and follow the correct operating procedures.

2.Regular cleaning and maintenance: Regular cleaning of the chuck’s sliders, guide rods, rollers and other components is the key to keeping the chuck running flexibly. Use an air gun or brush to remove impurities such as iron filings and dust, and clean thoroughly with an appropriate cleaning agent. At the same time, oil the key parts and lubricate with an appropriate amount of oil or lubricant to keep the chuck running smoothly.

3.Regular inspection and maintenance: Regularly check whether the parts of the laser pipe cutting chuck are damaged or worn. If any abnormalities are found, contact the after-sales personnel for processing immediately. In addition, oiling and cleaning are carried out regularly to prolong the service life of the chuck.

4.Through correct use, regular cleaning and maintenance, the laser cutting chuck can be kept in good condition, and its flexibility and operating efficiency can be improved. Keeping the equipment running stably and extending the life of the chuck will provide better performance and reliability for the laser cutting process.

▎Performance Parameter

| OD mm |

Centre-height mm |

Total Weight kg |

Inertia Kg.cm2 |

Repeatability mm |

Rotary precision mm |

| Φ282 | 145±0.05 | 107 | 5400 | ≤0.10 | ≤0.15 |

| Single Claw trip mm |

Single Claw thrust Kg.f |

Processing Range mm |

Permissible pressure Mpa |

Rated speed rpm |

thickness of pipe mm |

| 45 | 240 | 10-220 | 0.3-0.8 | 150 | ≥1 |

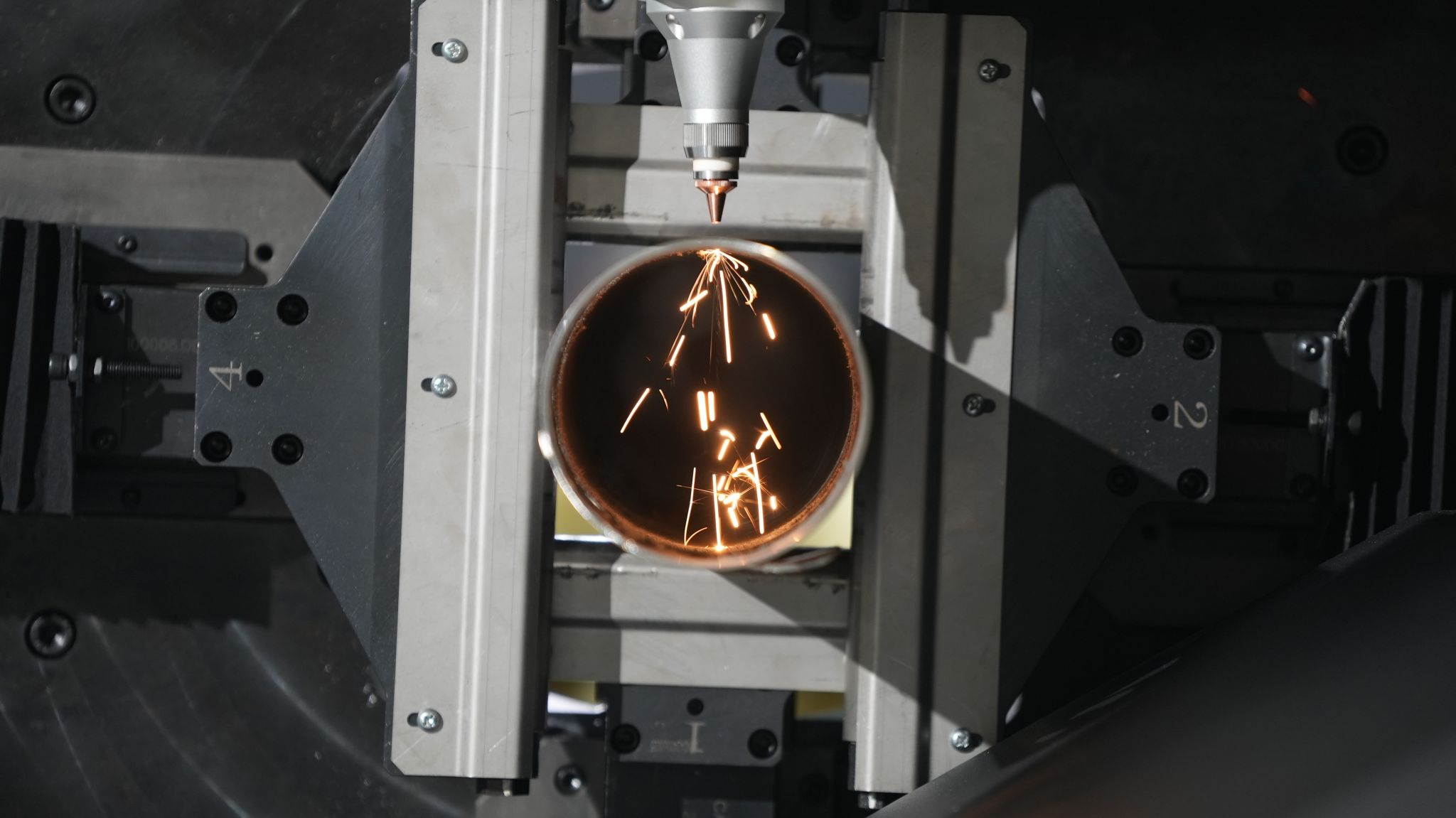

▎Application

The DRK-240JZ Pneumatic Chuck front clamp is equipped with the DRK-220JZ Pneumatic Chuck rear clamp. The Pneumatic Chuck has the characteristics of no material jam, dustproof, easy installation, and high cost performance. It replaces the traditional way of manual pipe cutting and reduces operations. The number of personnel increases the processing efficiency at the same time; the chuck of the laser pipe cutting machine is combined with the laser pipe cutting machine to use a variety of advantages, and it has become the first choice for metal pipe cutting.