▎Description

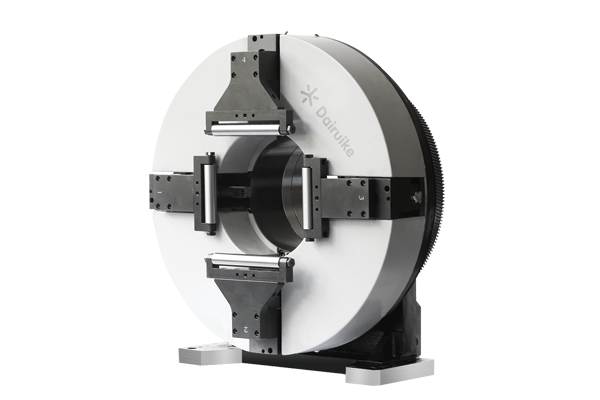

If you want an economical fiber laser cutter chuck, Dairuike 220JZ fiber laser cutter chuck may be the best choice for you. Dairuike 220JZ is a cost-effective laser pipe cutting machine designed to meet the cutting needs of pipes with diameters in the range of 10-220mm. It has excellent performance and economic benefits, and is an ideal choice for boosting the quality of pipe-sheet all-in-one machines and entry-level pipe cutters.

- This model adopts the technology independently developed by Dairuike, which has the advantages of precise transmission, small frictional resistance and smooth sliding. The jaws adopt a full-stroke design and are linked in pairs to precisely position the pipe to ensure cutting accuracy. At the same time, the machine also has the characteristics of large clamping force, wide clamping range and simple operation.

- The advantage of Dairuike 220JZ lies not only in performance, but also in economic benefits. It is a very cost-effective fiber laser cutter chuck, which can save cutting costs for users. In addition, fiber laser cutter chuck also has the characteristics of easy operation and easy maintenance, providing users with a convenient experience.

- The 220JZ fiber laser cutter chuck has many other advantages besides being economical. For example, it is convenient to use, simple to operate, and has a small volume and weight for convenient use. In addition, the maintenance cost of the chuck is relatively low, and does not require frequent maintenance and parts replacement, thereby saving the maintenance cost of the enterprise.

- Dairuike 220JZ fiber laser cutter chuck is designed with a wide seat support bearing seat, which can run stably at high speed to ensure cutting accuracy and cutting quality. At the same time, the chuck is equipped with a reducer base as standard, which has a simple structure and flexible selection, and can be flexibly installed according to the specific needs of users.

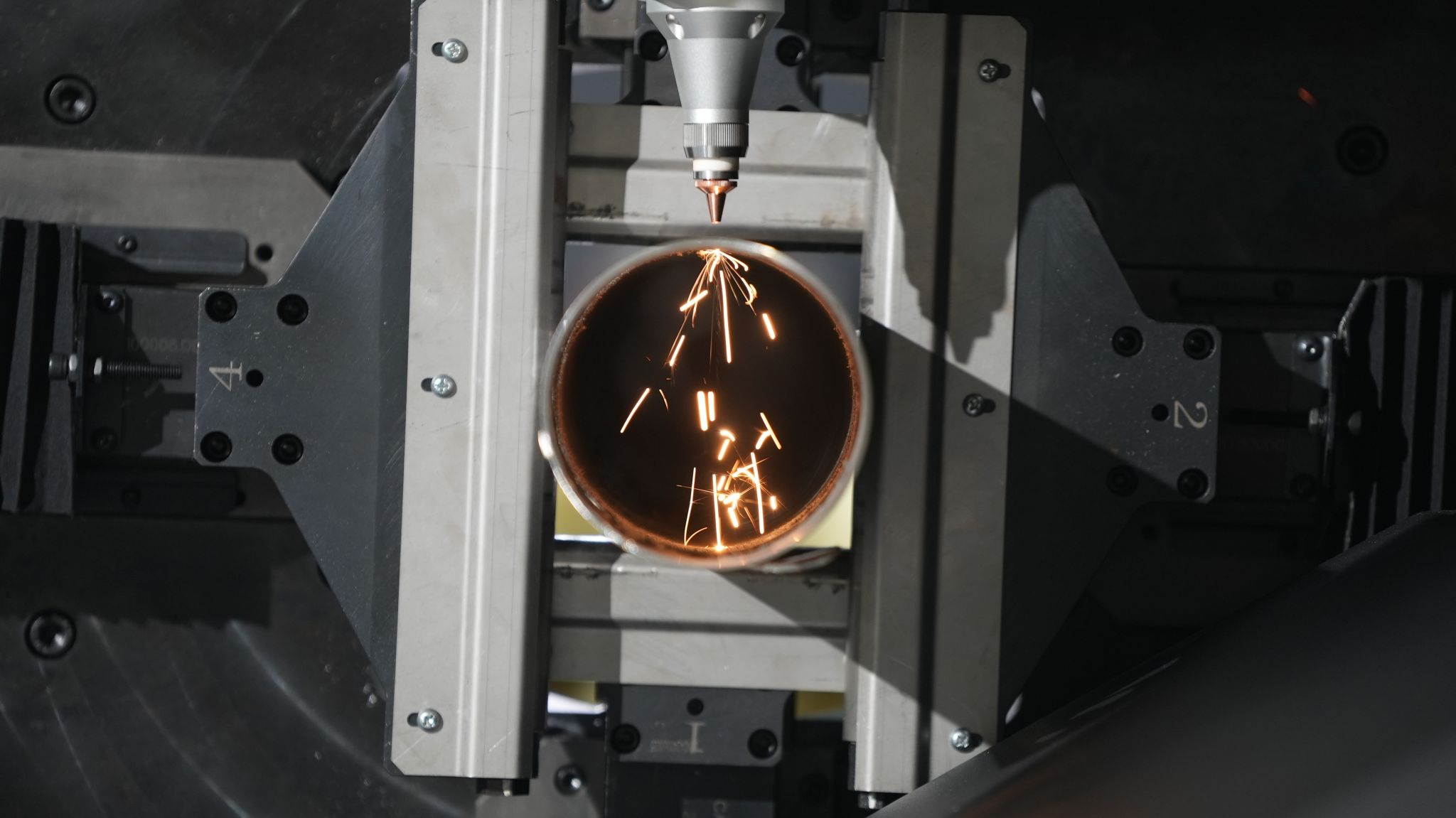

Dairuike 220JZ fiber laser cutter chuck can help users achieve high-quality processing results at a lower cost, solve the problems of low output and poor quality of finished products in the production process, and enable users to quickly seize production opportunities and realize batch processing of pipes . which improves competitiveness and obtains more and better orders.

▎How to choose the fiber laser cutter chuck suitable for laser pipe cutting machine?

1.Determine the pipe processing scope and future demand of the enterprise:

understand the pipe processing scope, processing materials and thickness of the enterprise, and predict the changes in market demand in the next few years. Based on this information, choose the chuck that is suitable for the small tube laser cutting machine.

2.Pay attention to the performance of laser cutting:

the performance of the core components directly affects the quality and efficiency of the laser cutting machine. Make sure you choose a fiber laser cutter chuck with high precision, stability and reliability to ensure precise cutting results.

3.Understand the supplier’s after-sales service:

choose a supplier with good after-sales service, and ensure that it can provide training and technical support. Understand the supplier’s after-sales service system, including training education system and technical support team, so as to be able to solve problems in time and improve production efficiency.

4.Refer to user evaluations and cases:

understand the evaluations and experience of other users, and you can understand the actual performance and reliability of the self centering chuck from the user’s point of view. At the same time, referring to some successful cases can also help to choose a suitable chuck.

To sum up, choosing a fiber laser cutter chuck suitable for a laser cutting machine needs to comprehensively consider factors such as enterprise needs, performance requirements and after-sales service. By carefully evaluating different options and communicating with suppliers, you can choose a high-quality chuck that suits your business to improve production efficiency and product quality.

▎Performance parameters

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (kg) |

Inertia (Kg.cm)2 |

Repeatability (mm) |

Rotary precision (mm) |

| Φ625 | Φ230 | 350±0.05 | 225 | 66000 | ≤0.05 | ≤0.05 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (Mpa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 110 | 220 | 10-220 | 0.3-0.8 | 150 | ≥1 | 12 |

▎Application

To sum up, the fiber laser cutter chuck is a high-precision, high-efficiency metal processing laser chuck widely used in various industries. It can improve production efficiency and product manufacturing accuracy, so it is widely used in many industries such as construction, automobiles, aerospace, rail transit, pressure vessel manufacturing, and steel metallurgy.