▎Description

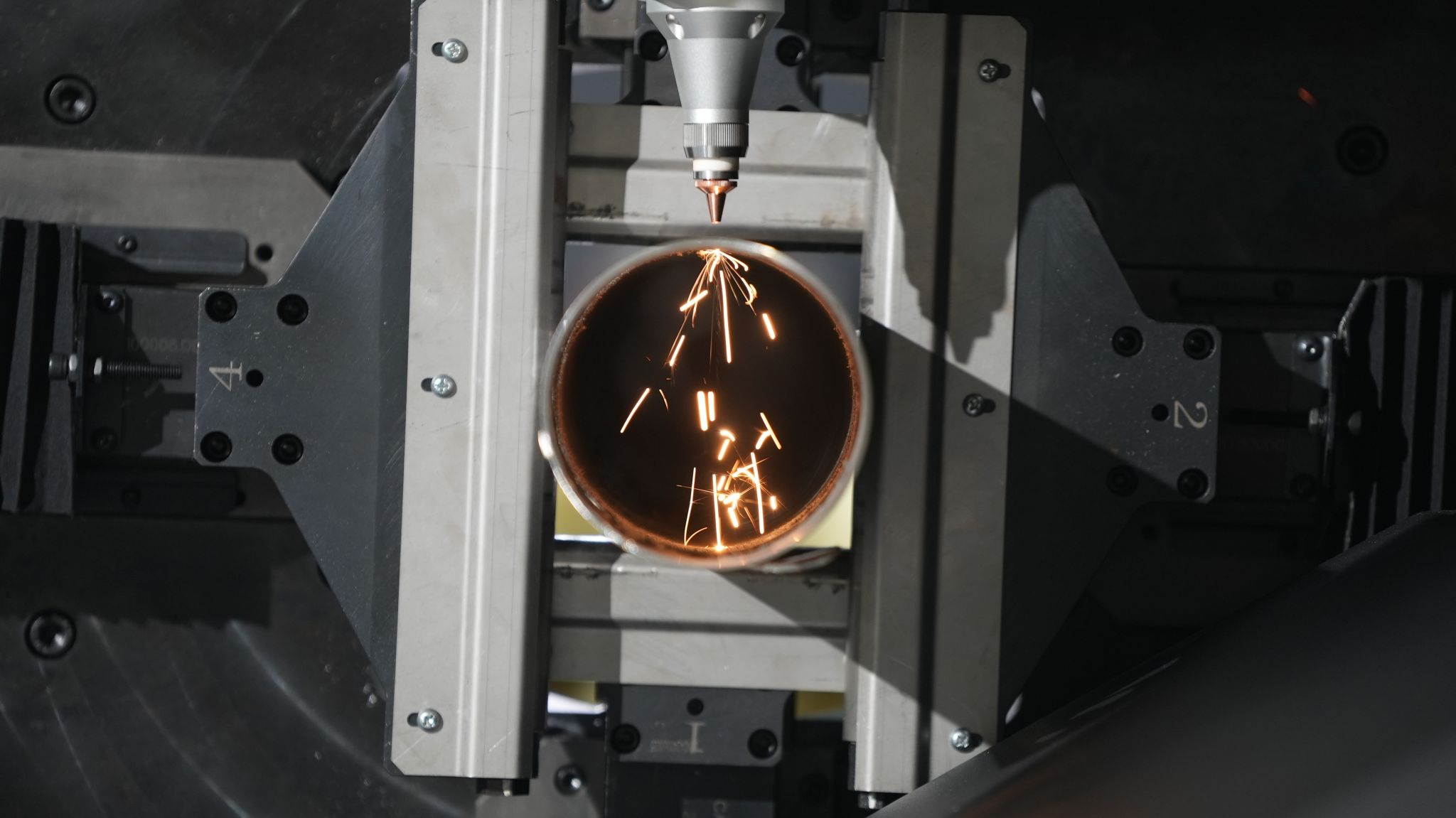

Allow me to recommend the most cost-effective laser rotary chuck available in the market. When it comes to laser rotary chuck options, there are indeed numerous choices available. However, one particular option that stands out in terms of efficiency and economy is the “220JZ fiber laser chuck” manufactured by DaiRuike. Let’s explore its features today!

- The Dairuike 220JZ laser rotary chuck boasts a rear chuck with a large single jaw thrust, ensuring stable and reliable pipe clamping. During the pipe clamping process, the rear chuck utilizes an extended barrel design that allows it to extend beyond the range of the front chuck. This feature maximizes material savings and effectively reduces costs. Additionally, the fiber laser chuck provides strong clamping force, capable of securely gripping heavy tubes, while maintaining high repeat positioning accuracy. This ensures stable and efficient clamping performance across different processing scenarios.

- The rear chuck of the Dairuike 220JZ laser rotary chuck works in conjunction with the front chuck to perform clamping and cutting operations on pipes. It can effectively clamp various pipes within a diameter range of 10-220mm, including round pipes, square pipes, special-shaped pipes, I-beams, and channel steels. This wide adaptability allows it to meet the needs of different processing scenarios. The laser rotary chuck provides users with efficient and stable processing solutions and has become an essential accessory in pipe processing.

- The rear chuck of the Dairuike 220JZ laser rotary chuck features a simple and clear design, making it easy to maintain. Crafted from high-quality materials, it is durable, reliable, and boasts a long service life, consistently delivering exceptional performance throughout its extended usage.

- The bearing housing is a critical component of the rear chuck. The bearing seat of the Dairuike 220JZ laser rotary chuck employs a wide seat support design, ensuring stability even during high-speed operations. Moreover, it comes equipped with a standard reducer base, offering flexibility and convenience in reducer installation and allowing users more freedom of choice.

In summary, the Dairuike 220JZ chuck with its rear chuck provides users with a cost-effective solution for fiber laser pipe cutting. With its efficient and stable performance, it is an ideal choice for a wide range of pipe processing applications.

▎Precautions For laser rotary chuck Installation:

1.Installation precautions:

Before installation, ensure that the working environment of the laser rotary chuck is dry, clean and meets safety standards.

Follow the laser rotary chuck installation manual to the letter and install the chuck correctly and tighten the bolts.

Check that the clamping force of the chuck is uniform to ensure that the tube is held firmly and does not slide or shift.

The clamp needs to be adjusted to the size and shape of the pipe to ensure that the pipe is clamped in the correct position.

2.Precautions for use:

The operator should be familiar with the operating procedures of the laser rotary chuck and follow the requirements of the operating manual.

During operation, fingers or other body parts are strictly prohibited from touching the laser rotary chuck to avoid injury.

Regularly check the chuck clamping force and positioning accuracy, and adjust or replace accessories in time if there is any abnormality.

During use, observe the laser rotary chuck for abnormal sounds, vibrations or wear and tear and deal with them promptly.

3.Maintenance:

Clean the chuck surface and fixture regularly to ensure that no debris or chips accumulate to avoid affecting the clamping effect.

Regular lubrication and maintenance in accordance with the laser rotary chuck maintenance manual to ensure the normal operation of the mechanical components.

Regularly check the bolts and fasteners of the chuck for looseness and tighten and make any necessary adjustments if they are loose.

Note: Before carrying out any installation, maintenance or adjustment, always read and follow the laser rotary chuck operating manual and safety manual and follow the instructions exactly.

▎Advantages of laser rotary chuck

In the field of metal processing, plasma cutting, flame cutting, CO2 laser cutting, etc. are relatively common cutting equipment. With the emergence of laser rotary chuck, these traditional equipment are gradually being replaced. So do you know what are the advantages of laser rotary chuck compared with other cutting methods? It is mainly reflected in the following aspects.

1. High cutting efficiency: small size, excellent moment of inertia, can adapt to high speed operation, high processing efficiency

2. Fast cutting speed: The laser cutting machine does not need to be clamped and fixed during the processing, which not only saves tooling fixtures, but also saves auxiliary time for loading and unloading.

3. Non-contact cutting: There is no contact with the workpiece during laser cutting, and there is no tool wear. Machining parts of different shapes without changing tools.

4. There are many types of cutting materials: laser rotary chuck can meet different pipe processing.

▎Performance parameters

| OD (mm) |

Centre-height (mm) |

Total Weight (kg) |

Inertia (Kg.cm²) |

Repeatability (mm) |

Rotary precision (mm) |

| Φ282 | 145±0.05 | 107 | 5400 | ≤0.1 | ≤0.15 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (Mpa) |

Rated speed (rpm) |

thickness of pipe (mm) |

| 45 | 240 | 10-220 | 0.3-0.8 | 150 | ≥1 |

▎Application

In the door and window guardrail industry, the application solution of laser rotary chuck has the following advantages:

Diversified processing: laser rotary chucks are suitable for various pipes used in the door and window guardrail industry, including square pipes, rectangular pipes, round pipes, oval pipes and special-shaped pipes. At the same time, it can also process tubular profiles such as angle steel, channel steel, I-beam, and T-beam. This makes the laser pipe cutting chuck have flexible processing capabilities in the process of making door and window guardrails.

Wide adaptability to materials: laser rotary chucks can be applied to a variety of metal pipes, including carbon steel pipes, stainless steel pipes, aluminum alloy pipes, copper alloy pipes, titanium alloy pipes, etc. This allows door and window guardrail manufacturers to choose suitable pipes for processing according to different design requirements.

High-precision processing: The laser rotary chuck adopts laser technology for cutting, and has high-precision and high-quality processing capabilities. It can realize various processing methods such as bevel cutting, hole opening, engraving, rotating hole, etc., to meet the processing needs of complex shapes and details in the door and window guardrail industry.

One-time molding: Compared with the traditional stamping process, the laser rotary chuck will not exert pressure on the workpiece during processing, so the workpiece will not be deformed. The processed workpiece does not need secondary grinding or trimming, and can be processed at one time, which improves production efficiency and saves production costs.

All in all, the application solution of laser rotary chuck in the door and window guardrail industry has the advantages of diversified processing capabilities, wide material adaptability, high-precision processing and one-time molding. It provides manufacturers of door and window guardrails with efficient, precise and flexible production tools, helping them achieve design innovation, improve production efficiency and product quality.