▎Description

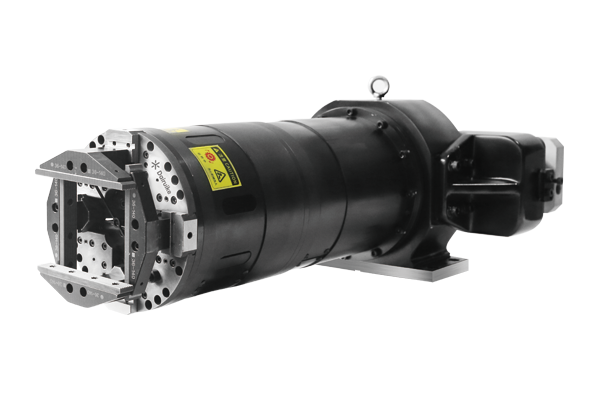

Let me recommend the most cost-effective self centering chuck on the market. Speaking of self centering chuck , there are really many options on the market. But the one that is really efficient and economical is the “220JZ fiber laser cutter chuck ” produced by DaiRuike. Let’s take a look at it today!

- The rear chuck of Dairuike 220JZ self centering chuck cooperates with the front chuck of Dairuike 220JZ self centering chuck to complete the clamping and cutting operations of pipes together, and can clamp various pipes with a diameter range of 10-220mm, including round pipes , square pipe, special-shaped pipe, I-beam, channel steel, etc., can adapt to the needs of different processing scenarios. The chuck can provide users with efficient and stable processing solutions, and has become one of the indispensable accessories in pipe processing.

- Dairuike 220JZ chuck has a large single jaw thrust at the rear of the chuck, which can ensure stable and reliable pipe clamping. In the process of clamping the pipe, the rear chuck of the chuck adopts a brand-new lengthened barrel design, which can extend out of the range of the front chuck, so as to save pipe materials to the greatest extent and effectively reduce costs. In addition, the self centering chuck has strong clamping force, can clamp heavy tube, and has high repeat positioning accuracy, which can provide stable and efficient clamping solutions in different processing scenarios.

- The bearing housing is an important part of the rear chuck of this chuck. The bearing seat of the rear chuck of the chuck adopts a wide seat support design, which can maintain stability under high-speed operation. In addition, it is also equipped with a reducer base as standard, which can make the installation of the reducer more flexible and convenient, and provide users with more freedom of choice.

- The rear chuck of Dairuike 220JZ chuck adopts a simple and clear design, which is easy to maintain and maintain. Manufactured with high-quality materials, it is durable and reliable, with long life and stability, capable of maintaining excellent performance over a long period of use.

Sales of self centering chuck continue to grow and their fields of application are expanding. With the improvement of the processing range and the change of industry demand, the traditional processing methods can no longer meet the needs of modern equipment processing. Choosing a new type of fiber laser cutter chuck equipment is an inevitable choice for enterprises to improve their processing capabilities.

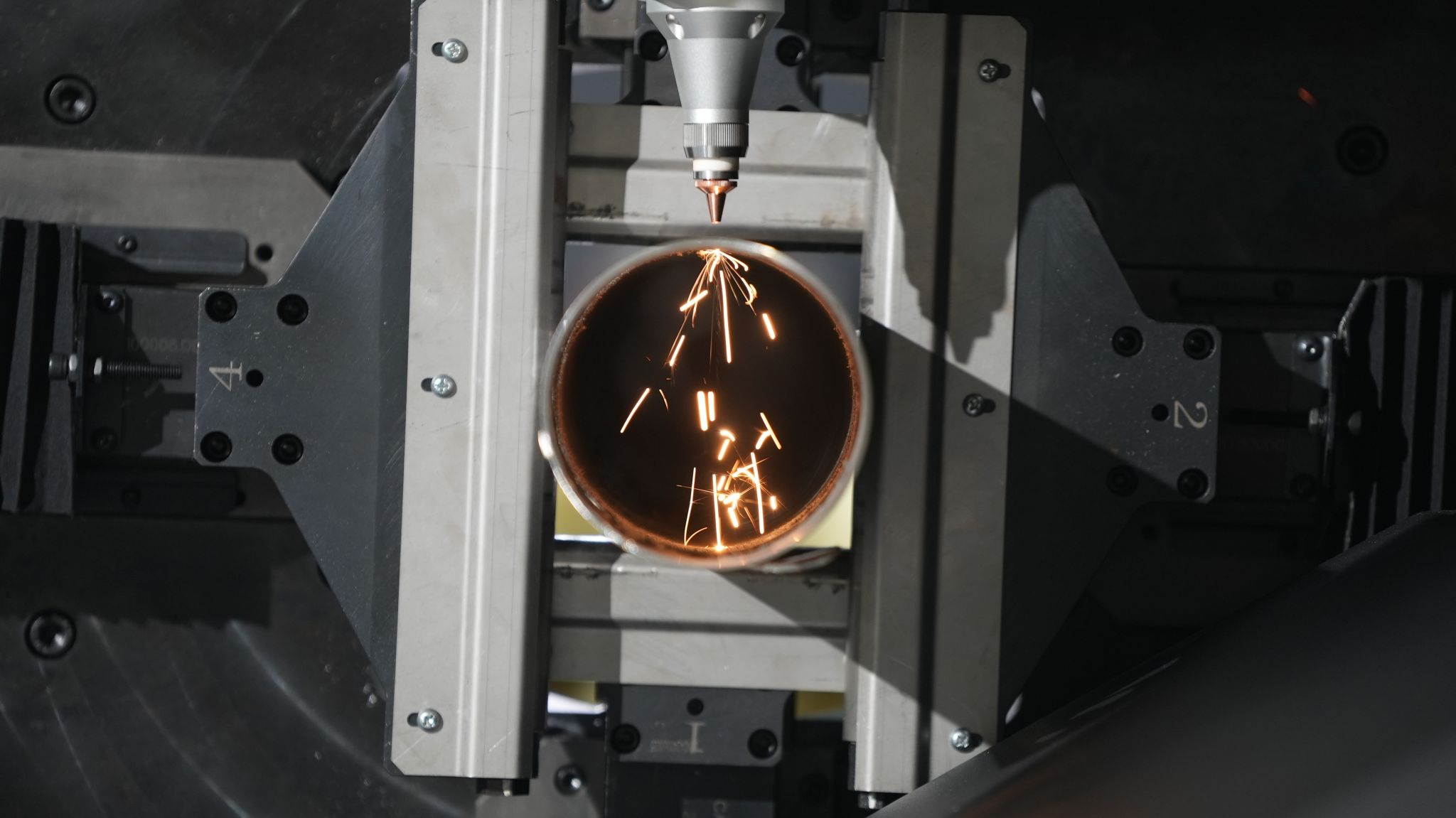

220JZ self centering chuck adopts high-precision laser technology, which can realize fast and accurate pipe cutting. It has many advantages, such as high efficiency, high precision, strong flexibility and so on. Therefore, self centering chuck is widely used in various industries, including metal processing, automobile manufacturing, aerospace, electronic equipment and other fields.

By choosing a new type of self centering chuck equipment that suits their own needs, enterprises can improve processing efficiency, reduce production costs, and improve product quality. It can cut complex shapes, reduce waste and save materials. At the same time, the self centering chuck also has the advantages of high automation, easy operation, and convenient maintenance, which further improves production efficiency and operational benefits.

▎How to choose a self centering chuck

When choosing a laser cutting chuck, there are indeed several important factors to consider, including brand, technological strength and key parameters.

Brand: Choosing a big brand can bring quality assurance and perfect after-sales service. Well-known brands such as Dairuike self centering chuck have a good reputation and a long-term brand history in the market. Its professionalism and considerate after-sales service provide users with a high-quality experience.

Scientific and technological strength: The scientific and technological quality of the self centering chuck is one of its core elements. It is necessary to choose products with good clamping stability, pay attention to the R&D strength and technological innovation capabilities of manufacturers, and ensure that products have advanced technological levels.

Key parameters: In addition to brand and technological strength, it is also important to pay attention to the key parameters of laser pipe cutting chucks. These parameters include processing range, processing speed, processing quality and processing cost. After testing and user research, Dai Ruike Laser Tube Cutting Chuck performed well and became one of the most popular brands.

High-quality laser tube cutting chucks need to stand the test of the market. As an old brand, Dai Ruike has brought cutting-edge laser clamping technology and upgrading experience to the market through precise control of market demand and continuous research and development, and has won praise and praise from users. recognized.

In general, when choosing a laser cutting chuck, brand reputation, technological strength and key parameters are factors worth considering. As a brand with advantages, Delica has performed well in these aspects, so it is a choice worth considering. However, the final choice should be made based on your specific needs, budget and situation.

▎DaiRuike and customers

Customer-centricity is one of the most important corporate values of Dairuike. This concept is rooted in thought, practiced in products, and implemented in action.

“Customer-centric, always adhere to the customer’s value-oriented, customer satisfaction as the evaluation standard.” Provide customers with continuous and valuable services, and strive to achieve a win-win situation with partners.

Dai Ruike maintains a long-term strategic partnership with customers to help customers improve production efficiency and provide customers with high-quality and trustworthy products and services. Through the professional technical support of Dairuike Laser Chuck, the equipment is regularly maintained, the service life is extended to the maximum, and excellent production quality and efficiency are maintained. Moreover, in the process of continuous improvement and tempering of the technology of both parties, we can grow together with our customers.

“We have experienced after-sales engineers in the self centering chuck industry. They have been in the laser chuck industry for many years and are also professional technicians in laser chuck applications. This is the basis for achieving high-quality services for customers.

Only those who understand technology can truly understand customer needs and effectively solve problems. Dai Ruike conducts technical training for after-sales service engineers every year, continuously improves the professional ability of the team, rationally uses on-line solutions, effectively solves most maintenance tasks, and provides customers with the best technical support.

Excellent quality comes from the pursuit of excellence in every detail. Taking a self centering chuck as an example, Dai Ruike strives to achieve excellence in the research and development of core components, as small as the materials used for each component. The stable and reliable operation of equipment will greatly reduce the long-term cost of production. To maintain and increase value for customers.

▎Shipping of self centering chuck

The transportation of the laser chuck is a key link, and the following aspects need to be paid attention to:

Packaging Protection: Before shipping the laser chuck, ensure that it is properly packaged for protection. Use sturdy packing material, such as a wooden box or suitable packing box, to protect the laser chuck from bumps, vibrations, and other physical damage.

Fixed and stable: In the package, make sure the self centering chuck is fixed and stable to prevent it from moving or tilting during transportation. Use a fixture to ensure that the laser chuck remains in a secure position.

Clear marking: Clearly mark the content, weight, size and other necessary information of the self centering chuck on the package. This helps transporters properly handle and manipulate the packaging and ensure it is treated properly during transit.

Logistics options: Choose a reliable logistics service provider with the experience and expertise to transport laser chucks safely. Make sure to talk to the shipping company and understand their packaging, handling and insurance policies.

Tracking and Monitoring: For critical laser chuck shipments, use a tracking and monitoring system to track the location and status of the shipment. This can help to detect any problems in time and take necessary measures to deal with them.

Receiving inspection: After the self centering chuck arrives at its destination, a careful receiving inspection is carried out. Check the integrity of the packaging and the laser chuck for any damage. If any problems are found, contact the logistics company in time and record the relevant information.

To sum up, when transporting laser chucks, it is necessary to pay attention to packaging protection, fixing and stability, clear identification, selection of reliable logistics service providers, tracking monitoring and receiving inspection. These measures can help ensure the safety and integrity of laser chucks during transport.

▎Performance parameters

| OD (mm) |

Centre-height (mm) |

Total Weight (kg) |

Inertia (Kg.cm²) |

Repeatability (mm) |

Rotary precision (mm) |

| Φ282 | 145±0.05 | 107 | 5400 | ≤0.1 | ≤0.15 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (Mpa) |

Rated speed (rpm) |

thickness of pipe (mm) |

| 45 | 240 | 10-220 | 0.3-0.8 | 150 | ≥1 |

▎Application

self centering chuck have a wide range of applications in many industries, including but not limited to the following:

Decoration industry: self centering chuck can be used for the processing of metal decorations, furniture accessories, etc. Through laser cutting, various complex patterns and shapes can be cut to meet the needs of the decoration industry for personalization and customization.

Automobile industry: self centering chuck play an important role in the automobile manufacturing industry and are used for cutting metal parts such as body, door, and roof. Laser cutting can achieve high-precision and high-efficiency cutting, improving production efficiency and product quality.

Fitness equipment manufacturing industry: Fitness equipment is usually made of metal materials. self centering chuck can be used to cut pipes and make metal parts such as equipment racks and barbells to improve production efficiency and product quality.

In addition, self centering chuck can also be used in electronic and electrical industries, aerospace industries, metallurgical industries and other fields. With the continuous development and innovation of technology, the application range of laser cutting machines will continue to expand.