▎Description

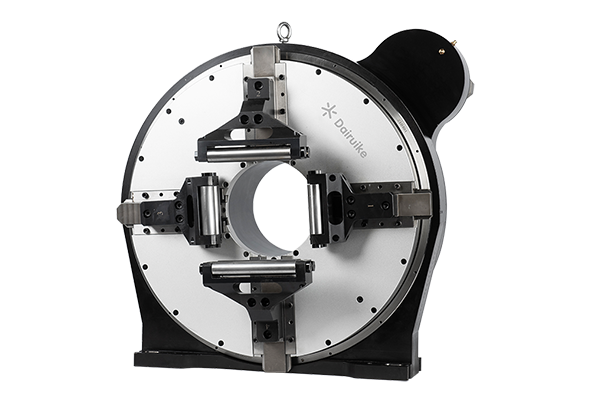

- DRK-160 laser pipe cutting chuck inherits the excellent genes of DRK-120 laser pipe cutting chuck for stability, high precision and precision. It has powerful functions and can be upgraded to process small pipes. It is a high-precision, high-speed, high-performance pipe cutting developed for pipes below 165mm. Machine small pipe series laser pipe cutting chuck.

- DaiRuike laser pipe cutting chuck is suitable for laser pipe cutting machine equipment, which facilitates mass production and has high efficiency. DaiRuike laser pipe cutting chuck is independently developed, with a clamping concentricity of ≤0.1mm, and can clamp pipes of different diameters and cross-sections without changing the jaws. The front laser pipe cutting chuck clamps the full stroke without changing the jaws, and the rear laser pipe cutting chuck is equipped with an air blowing function, which can effectively improve the accumulation of waste residue in the jaws, high-speed empty stroke, high acceleration, and cutting response.

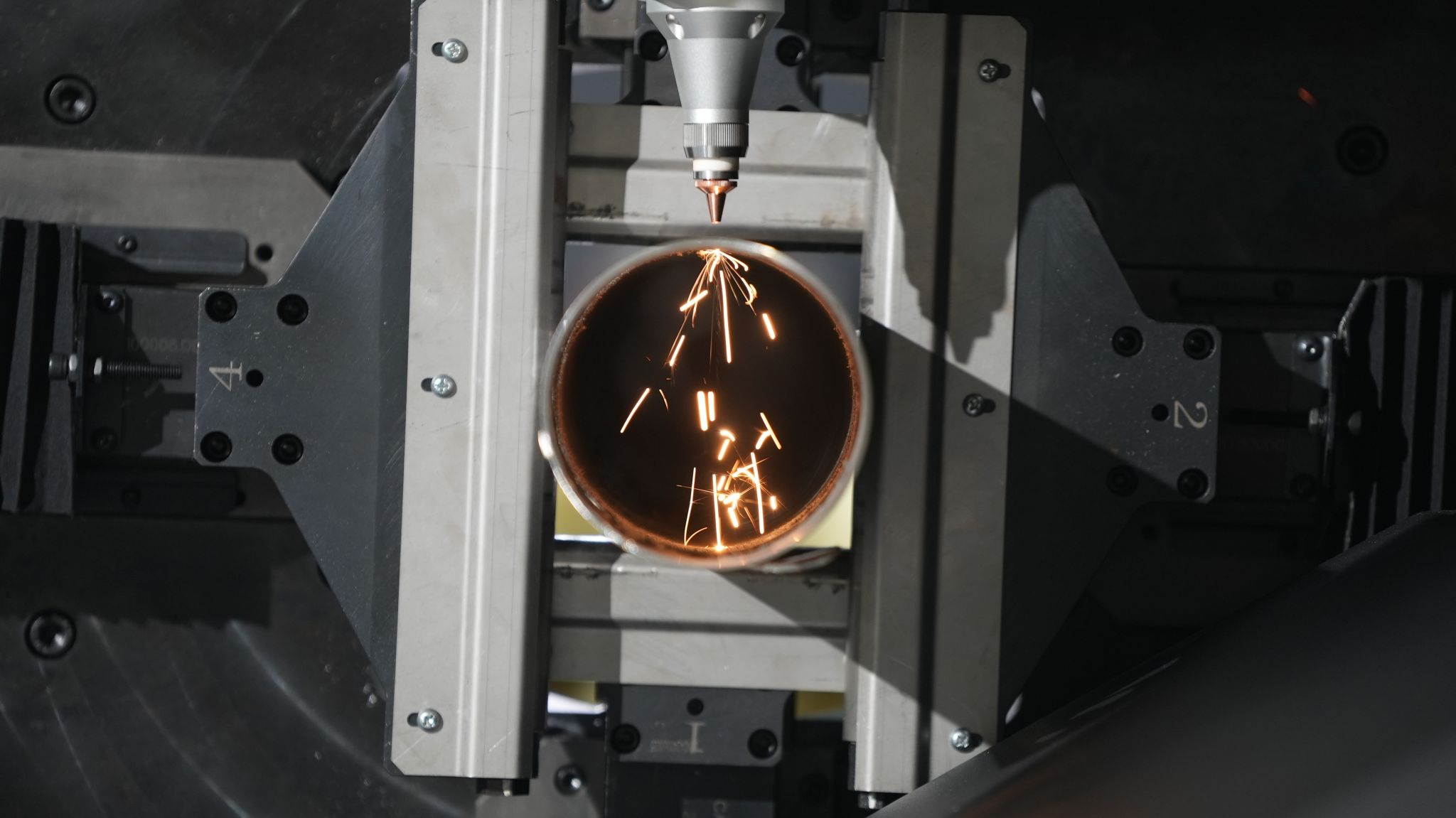

- The laser pipe cutting chuck is an essential accessory for laser cutting machines. It provides clamping and feeding functionality for tubes during the pipe cutting process. This versatile chuck is capable of clamping various types of pipes, including round pipes, rectangular pipes, channel steels, I-beams, angle steels, and special-shaped pipes. It is designed to accommodate different materials, ensuring flexibility in the cutting process.

- This laser pipe cutting chuck accelerates empowerment, expands the metal small tube processing market, and ignites a “new engine” for high-quality development. The speed is above 150r/min. The processing efficiency of the whole machine is 65% higher than that of traditional processing, and the repeat positioning accuracy is ≤0.05mm. Professional solution Small tubule cutting complications.

- DRK-160 laser pipe cutting chuck is pneumatically opened and clamped, with large and stable clamping force, no need to adjust the jaws for clamping pipes within the full stroke range, powerful relaxation, precise clamping, large inner hole of the chuck, and high safety of automatic loading and unloading. The integral built-in drive structure greatly improves the transmission accuracy and stability. Low noise, top grinding precision in the industry. The laser pipe cutting chuck gear is sealed and dust-proof, reducing maintenance frequency and prolonging the service life of the laser chuck. The laser pipe cutting chuck has less residual material, which improves the utilization rate of the pipe, and the rear chuck can maximize the output of the front chuck, shortening the distance between the cutting head and the jaws of the rear chuck, and the tail material is short.

Dairuike laser pipe cutting chuck is dedicated to providing innovative and customer-centric solutions in the field of laser cutting technology. With a strong focus on continuous improvement and customer satisfaction, we strive to exceed expectations and deliver exceptional value to our customers.

Our team of experienced engineers and technicians is at the forefront of technological advancements, developing cutting-edge laser pipe cutting chuck solutions that cater to the evolving needs of the industry. We are committed to delivering high-quality products that offer precision, reliability, and efficiency in the cutting process.

What sets us apart is our customer-centric approach. We understand that each customer has unique requirements and challenges, and we work closely with them to provide tailored solutions that address their specific needs. Our dedicated support team is always available to assist with installation, training, and technical support, ensuring a seamless experience throughout the entire customer journey.

Furthermore, we prioritize continuous research and development, investing in the latest technologies and manufacturing techniques to stay ahead of the competition. We are committed to innovation and constantly strive to push the boundaries of what is possible in laser cutting technology.

At Dairuike, we believe in building long-lasting relationships with our customers based on trust, integrity, and mutual success. We are driven by their success and are dedicated to helping them achieve their goals. With our expertise and commitment to excellence, we are confident in our ability to meet and exceed the expectations of our customers in the small pipe market and beyond.

▎How to choose a small pipe cutting chuck?

1.Understand the scope and needs of the enterprise’s pipe processing:

Clarify the enterprise’s pipe processing range, processing materials and thickness, and forecast the future market. This will help determine the type and specification of laser pipe cutting chuck needed.

2.Understand the performance requirements of laser cutting:

Different laser pipe cutting chuck has different properties, such as precision, speed and stability. According to the needs and requirements of the enterprise, choose the chuck with the performance that meets the enterprise.

3.Consider after-sales service:

Choose a supplier that provides professional training and technical support, which can help enterprise customers get started quickly and solve possible problems. High-quality after-sales service can ensure the normal operation and efficient use of the laser pipe cutting chuck.

4.Quality and reliability:

Choose a supplier with a good reputation and high quality to ensure the quality and reliability of the laser pipe cutting chuck. This increases productivity, reduces downtime, and extends equipment life.

5.Cost-effectiveness:

Consider the price and performance of the chuck comprehensively, and choose the chuck that is most suitable for the enterprise’s budget. At the same time, we should not only pay attention to the price, but also consider the performance, reliability and long-term use benefits of the chuck.

When selecting a chuck for a small pipe laser cutting machine, comprehensively consider the above factors, and fully communicate and understand with the supplier to ensure that you can choose a high-quality chuck product that suits the needs of the enterprise.

▎Performance parameter

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm 2) |

Repeatability (mm) |

Rotary precision mm |

| Φ590 | Φ170 | 290±0.05 | 195 | 34000 | ≤0.05 | ≤0.05 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (Mpa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 81 | 120 | 10-160 | 0.3-0.8 | 150 | ≥1 | 12 |

▎Application