▎Description

- In the realm of heavy tube processing, the demand for advanced equipment has surged with the advent of a new era of large-scale infrastructure projects. From petrochemicals to rail transportation, construction bridges to engineering machinery, and even aerospace, the heavy pneumatic chuck has emerged as a pivotal tool driving economic development.

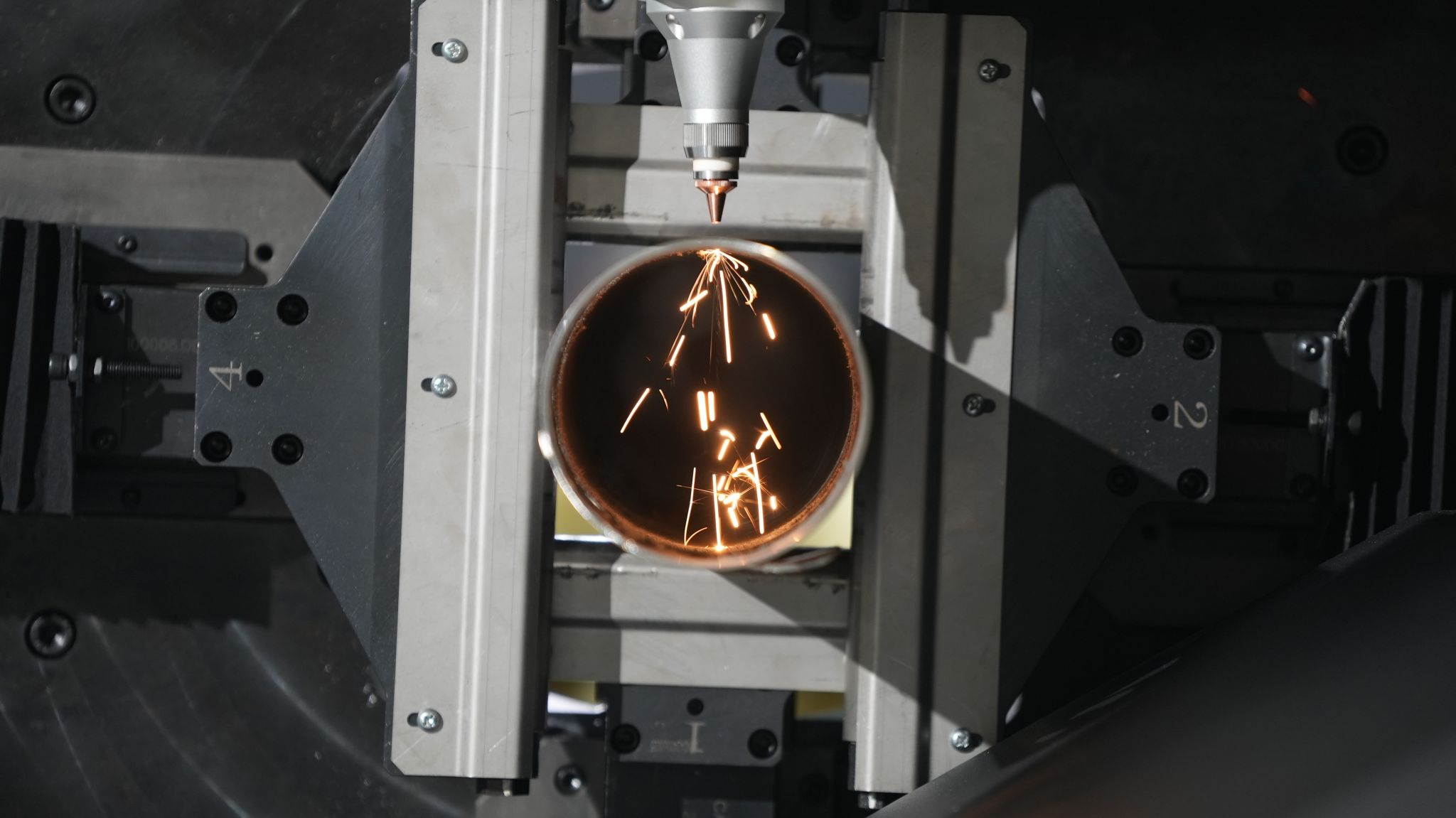

- At the forefront of meeting this escalating demand is the DRK-360FS heavy pneumatic chuck. Unveiling a breakthrough in heavy tube cutting, this chuck boasts a versatile three-chuck/four-chuck system, enabling zero tail material waste. Its adaptability is further enhanced by various side-hanging methods, presenting options like integrated side hanging or split side hanging, streamlining the loading and unloading processes.

- Seeking the ideal solution for heavy tube processing needs? The DRK-360FS full-stroke square heavy pneumatic chuck offers a comprehensive answer. With square and round sizes harmonized and a wide processing range covering tubes from 20mm up to a substantial 360mm, this chuck is designed to tackle diverse challenges. Notably, it exhibits remarkable load capacity for I-beam/channel steel, The maximum size can reach to 32# and boasting a load capacity of 1000kg across two pneumatic chucks.

- Addressing the laser cutting requirements of medium and heavy tubes, the pneumatic chuck of the heavy fiber laser tube cutting machine undergoes further enhancements with a heavy centering chuck. This upgrade significantly amplifies clamping force, elevating tube load-bearing capacity to ensure processing stability and cutting precision. Featuring a full-stroke design, wide and narrow jaws, and support for large I-beam channels, it offers an efficient solution for heavy-duty and large-diameter pipes. With a maximum clamping capacity of 360mm, it can seamlessly process entire pipes extending up to 12m in length.

- The DRK-360FS heavy pneumatic chuck stands out with its optional three-chuck or four-chuck side hanging design, enhancing safety during loading and unloading while mitigating the challenges of handling heavy tubes. The gear-sealed, dustproof design reduces maintenance frequency, extending the operational life of the pneumatic laser chuck.

- In essence, the DRK-360FS heavy pneumatic chuck represents a paradigm shift in heavy tube processing. Its efficiency, superior quality, and broad application spectrum outshine traditional methods, positioning it as the equipment of choice for those venturing into the demanding domain of heavy tube processing.

▎Performance parameter

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm 2) |

Repeatability (mm) |

Rotary precision mm |

| Φ890 | 370×370 | 465±0.05 | 660 | 400000 | ≤0.05 | ≤0.05 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (M pa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 176 | 920 | 20-360 | 0.3-0.8 | 50 | ≥3 | 12 |

▎Dairuike Serve

We warmly invite customers at home and abroad to visit our factories and offices to experience our professional services in person and conduct business negotiations. We can better understand your needs and provide customized services.

From the moment you receive your laser chuck, we are committed to providing you with full support. Your dedicated sales representative and our factory technical experts will work together to ensure that any after-sales issues you encounter while using our products are resolved promptly and effectively.

We understand the importance of technical support for the use of equipment, so we provide comprehensive free online training and technical support services to ensure that you can fully master the operation and application of laser chucks. In addition, our technical team can also go directly to your location to assist in the installation, commissioning, and training of the equipment, as well as solve any problems during use. Our goal is to ensure that you can use our products smoothly and efficiently to improve your work efficiency and product quality.

▎Application

The widespread application of heavy pneumatic chucks has indeed brought many benefits to several industries. The following are the main application areas and advantages of this technology:

Heavy industry machinery: a heavy pneumatic laser chuck is widely used in heavy industry machinery, such as pipe cutting and processing of large machinery and equipment such as excavators, loaders, and cranes. It can efficiently and accurately cut and process pipes of different shapes, providing better process adaptability and production efficiency.

Steel structure construction: Heavy pneumatic chucks are widely used in the field of steel structure construction. It can be used to cut and process various types of pipes, including round pipes, square pipes, channel steel, angle steel, oval pipes, etc. This flexibility makes the pneumatic laser chuck ideal for efficient, precise cutting in steel construction.

Construction: In the construction industry, heavy laser chucks are used to cut and process pipes, pipelines, trusses, and other structures. It provides precise cutting results, ensuring pipe quality and fit while improving construction efficiency and accuracy.

Machinery Manufacturing: Heavy metal pneumatic chucks play an important role in the machinery manufacturing industry. It can be used to cut and process tubes of all shapes, including tubes for mechanical structures, components, and assemblies. By using the laser pipe-cutting chuck, high-precision and high-efficiency pipe processing can be realized to meet the needs of mechanical manufacturing.

Bridge Engineering: Heavy pneumatic chucks are widely used in pipe cutting and processing in bridge engineering. It can handle pipes of all shapes and sizes, including those used in bridge structures and supports. Laser tube chucks provide precise cutting and machining results, ensuring tube quality and fit.

In general, the heavy pneumatic chuck has a wide range of applications, can provide high-precision and high-efficiency pipe cutting and processing solutions, fills in the shortcomings of traditional processing methods, and improves processing efficiency and product quality.